Saelim GMT

Business

Business

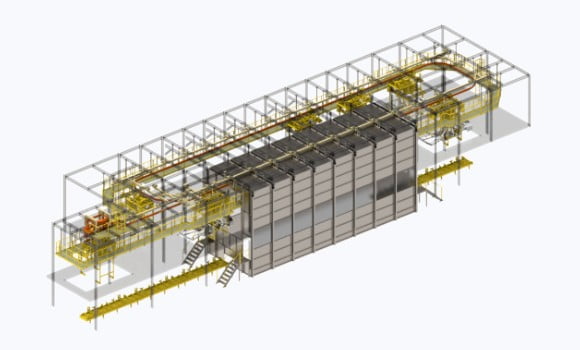

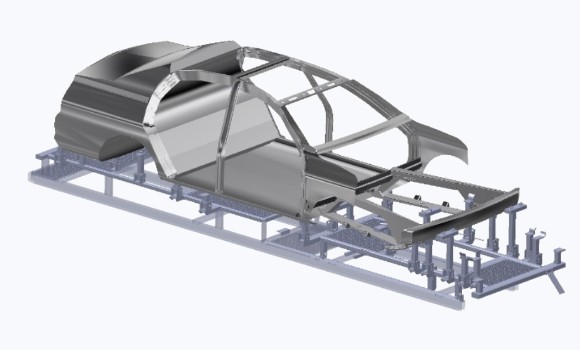

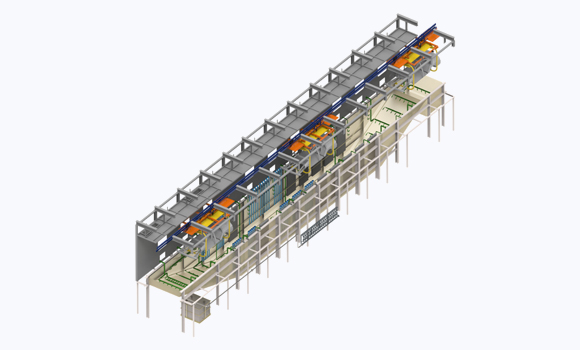

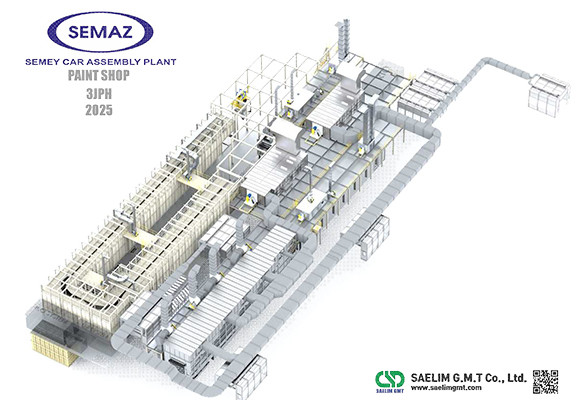

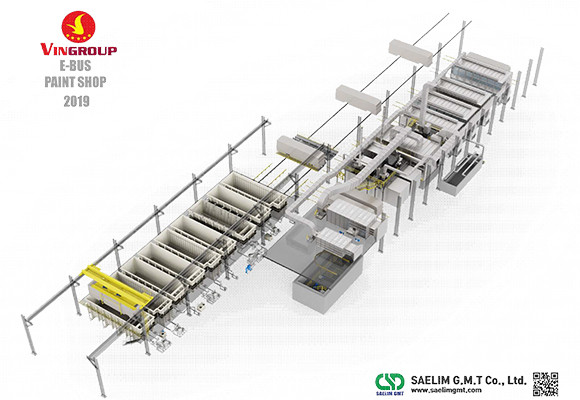

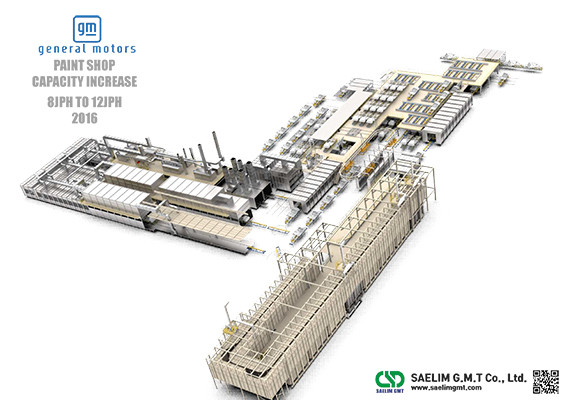

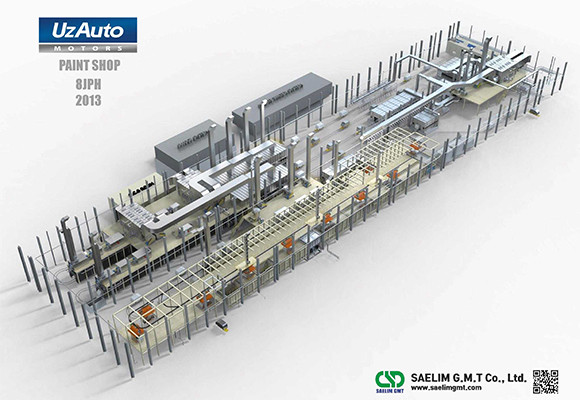

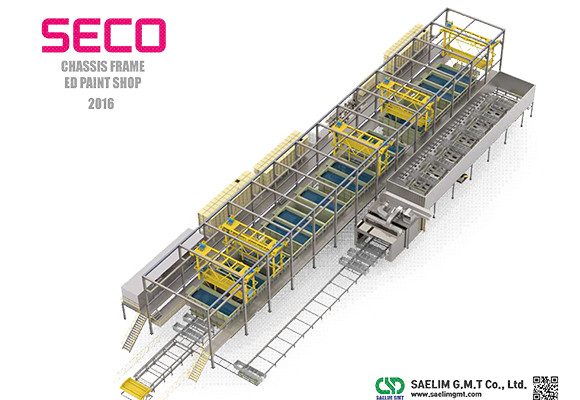

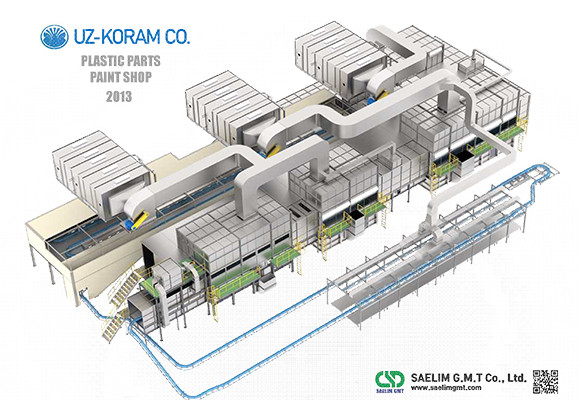

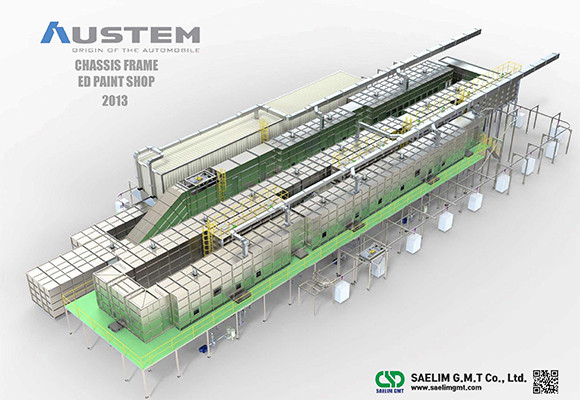

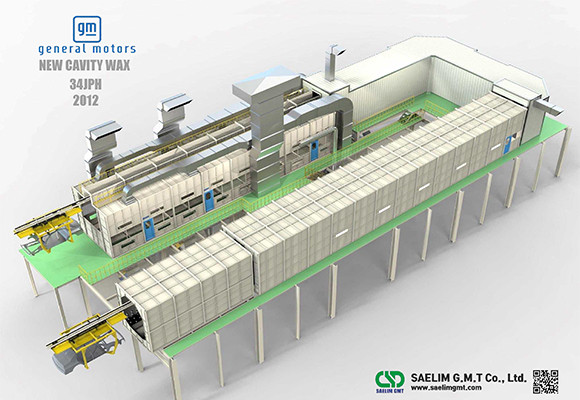

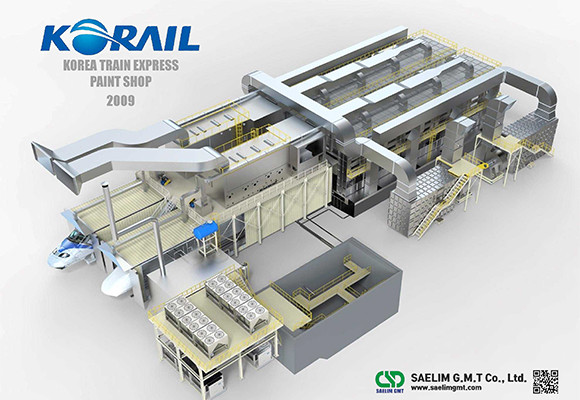

Painting Plant and Painting System

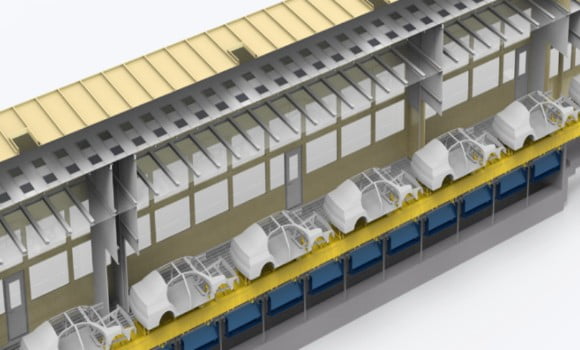

Painting Plant Concept

Saelim GMT Co., Ltd. provides a wide range of diverse painting solutions.

Based on our extensive know-how, we utilize the information obtained through proven operations in the field to develop plans and install new equipment.

In addition, we optimize and modernize existing installations to meet our customers' needs and take the lead in providing effective painting solutions for vehicles and transportation.

Painting system

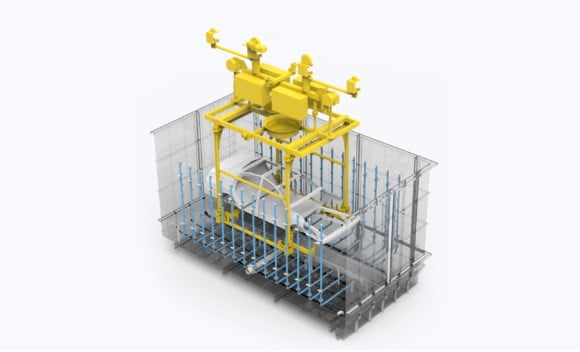

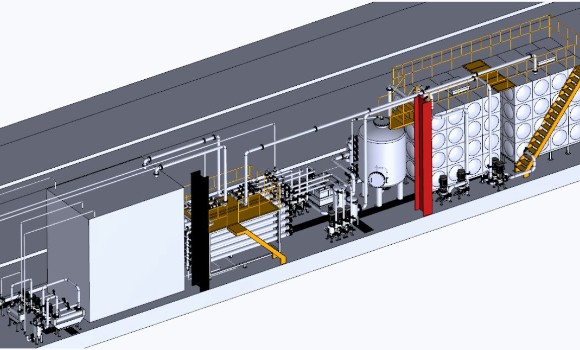

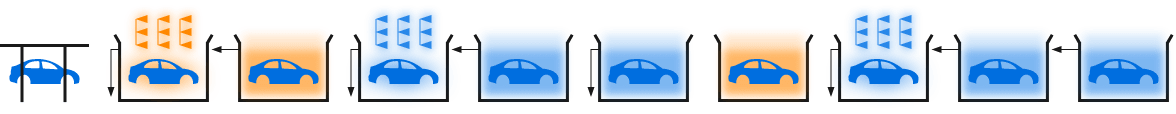

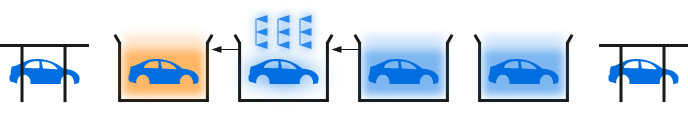

Pretreatment

The pretreatment equipment is a device that cleanly removes contaminants (oil, dirt, etc.) on the body and the surface of the metal and forms a chemical film on the metal surface.

This strengthens the corrosion prevention performance of the body and the object to be coated, and improves the adhesion of the electrodeposited coating film.

| Stage 1 | Stage 2 | Stage 3 | Stage 4 | Stage 5 | Stage 6 | Stage 7 | Stage 8 | Stage 9 | |

|---|---|---|---|---|---|---|---|---|---|

| Loading | Pre Degrease | Degreasing | Rinse No.1 | Rinse No.2 | Condition | Phosphate | Rinse No.3 | Rinse No.4 | D.I Rinse |

| Deck | Spray in dip | Dip | Spray in dip | Dip | Dip | Dip | Spray in dip | Dip | Dip |

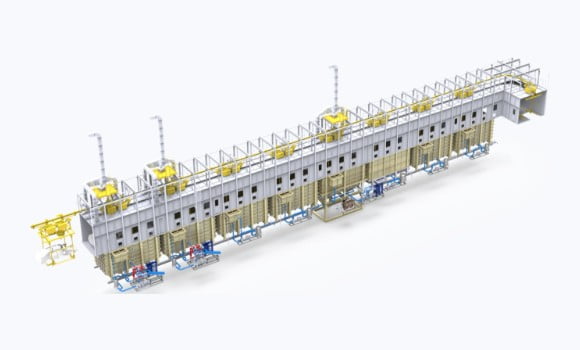

Electrodeposition

Electrodeposition equipment is equipment that uses the potential difference between two electrodes to move electrically charged paint particles to the body and surface of the object with opposite charges.

During this process, the coating is precipitated to form a uniform coating on the inside and outside of the body and the object to be coated, strengthening the corrosion prevention performance and greatly improving the corrosion resistance.

| Stage 1 | Stage 2 | Stage 3 | Stage 4 | ||

|---|---|---|---|---|---|

| Inspection Station |

ELPO | UF 1 Rinse | UF 2 Rinse | D.I Rinse | Uploading

Station |

| Deck | Dip | Spray in dip | Dip | Dip |

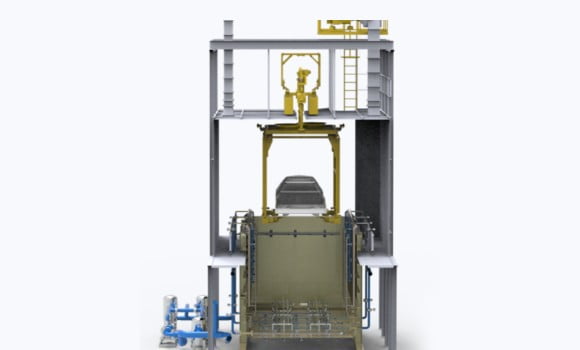

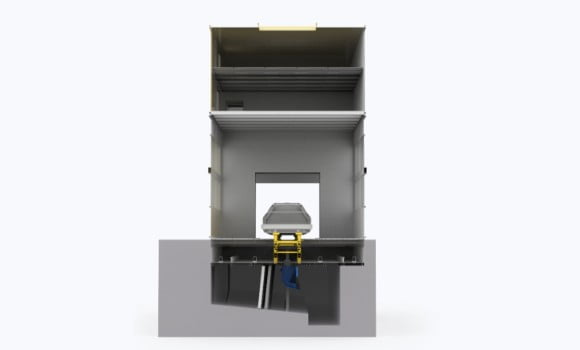

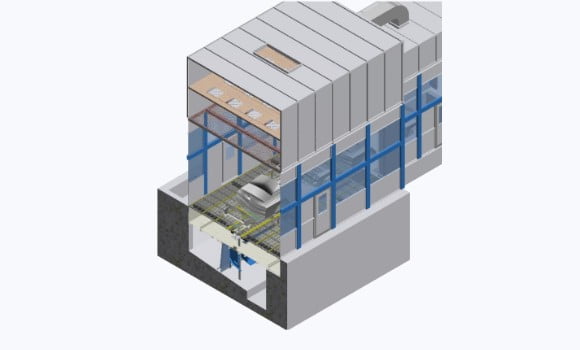

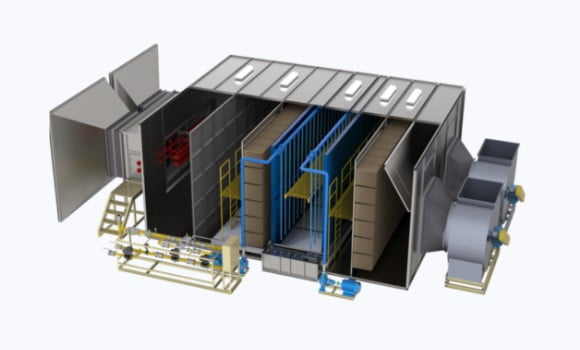

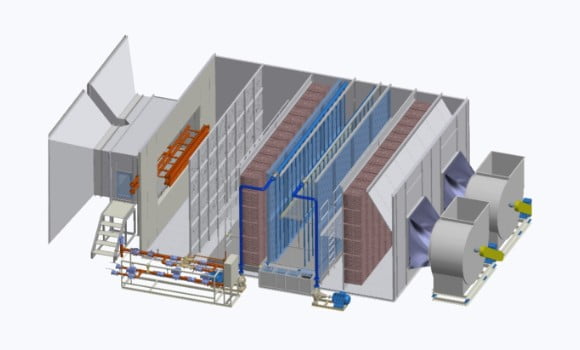

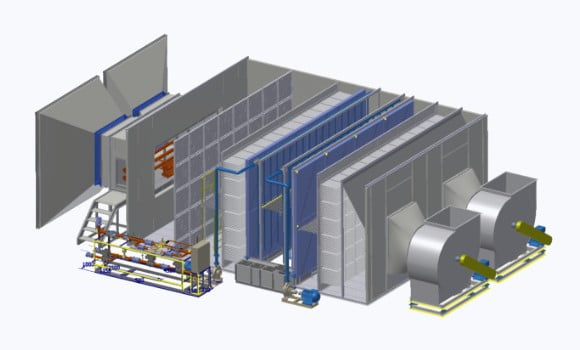

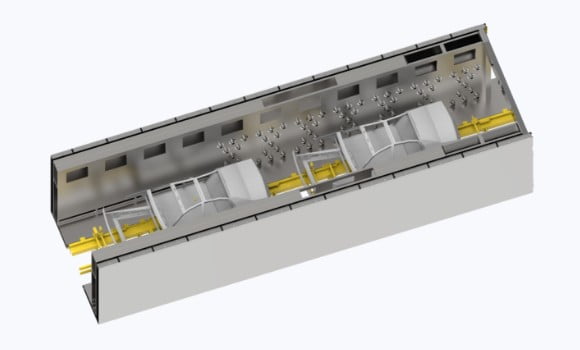

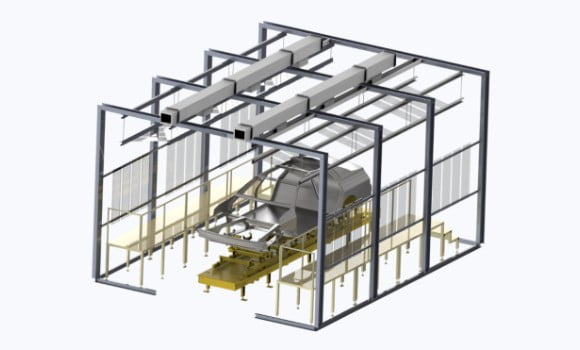

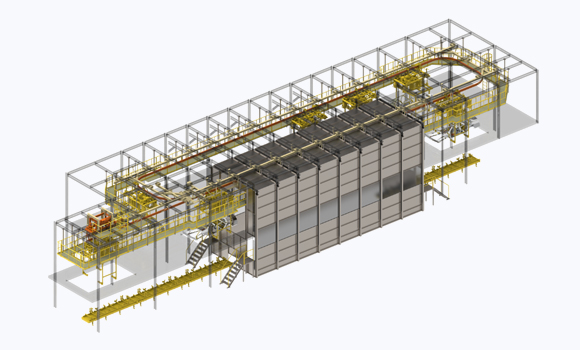

Booth

The paint booth equipment is a device that performs the process of applying paint to the body and the surface of the object to be painted.

This improves the paint quality and appearance, thereby enhancing the completeness of the product.

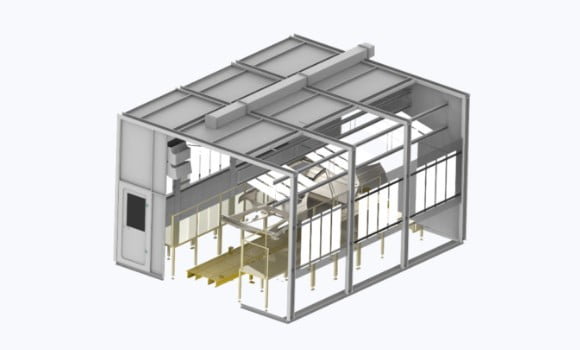

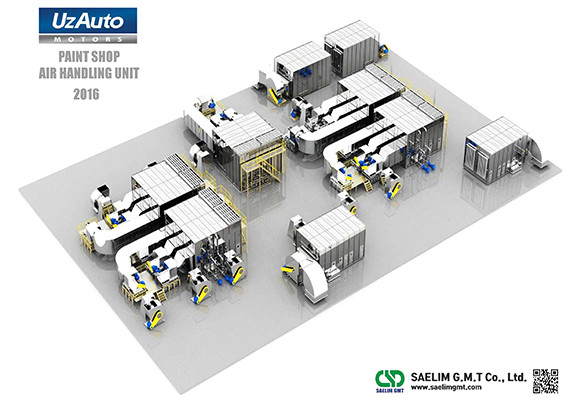

ASH(Air supply House)

ASH equipment is equipment that maintains an appropriate environment by effectively controlling the temperature and humidity of the painting booth and workshop.

This provides optimal conditions for booths and workshops and contributes to high-quality painting.

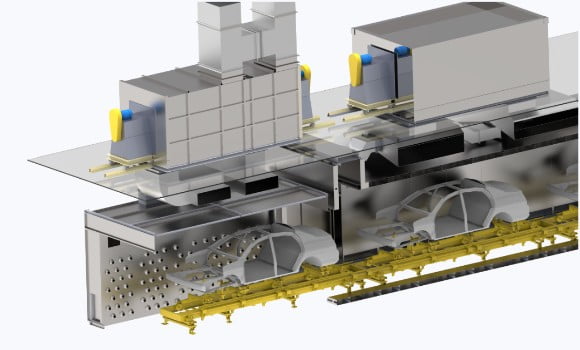

Baking Oven and cooling system

This provides a system that optimizes the drying process to more firmly adhere and cure the sprayed coating to the body.

This improves the quality of the paint job and enhances the durability of the coating. Saelim GMT uses the latest technology and processes to form a more effective coating on the vehicle surface, increase the durability of the paint, and ensure robustness against external environments. This optimized drying system contributes to the pursuit of high quality and efficiency in vehicle painting.

Working zone

It optimizes the smartly designed work area to create an efficient working environment where workers can fully concentrate.

This provides solutions to efficiently perform tasks such as sanding, spot work, repairs, and quality control. Optimizing the workspace helps workers focus on their work effectively, and improves the accuracy and productivity of their work. This structured work environment provides our customers with the opportunity to maintain quality and maximize efficiency.

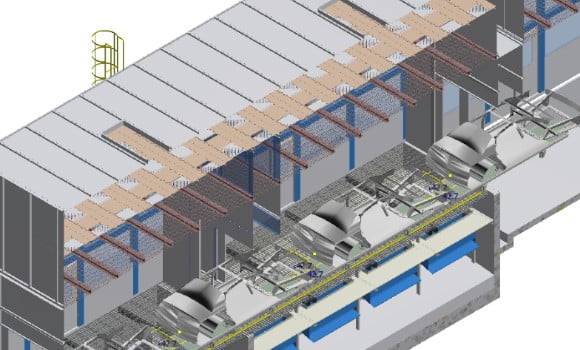

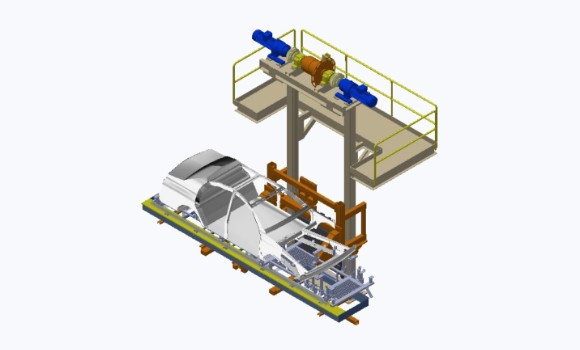

Robot automated painting

Saelim GMT robotic painting system is specifically designed for automated painting of large volumes of surfaces.

This system covers the entire paint surface required by the customer in both the interior and exterior areas of the vehicle. It provides a more rigorous and precise system to achieve the quality and optimum economy of all paint materials including water-soluble and powder paints. Saelim GMT's robotic paint system improves efficiency and consistency, while contributing to maintaining an environmentally friendly paint process.

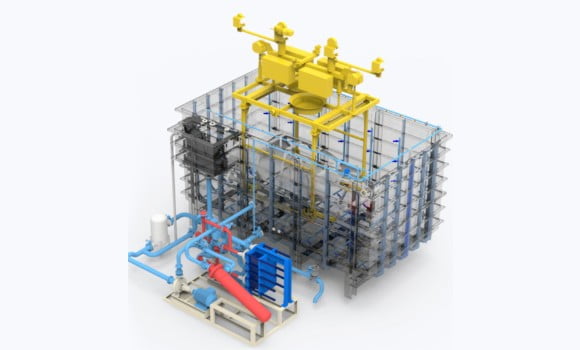

Paint and sealer supply equipment

It offers a variety of paint supply devices to ensure accurate paint thickness and high precision.

These various devices control the precise supply and spraying of paint to meet the quality level required by the customer. This allows Saelim GMT to maximize efficiency while maintaining consistent quality in the painting process. Customers can achieve the desired painting results through these precise paint supply devices.

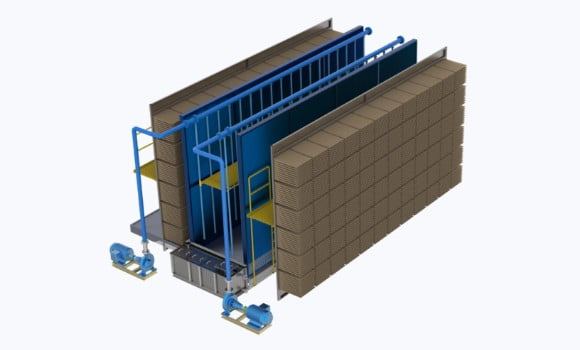

Paint sludge removal equipment

Saelim GMT precisely understands the various properties of paints to improve the efficiency of the painting system.

In particular, overspray that does not reach the body surface during spraying is effectively managed inside the paint shop. To this end, Saelim GMT has introduced a paint separation device to filter and discharge overspray. This minimizes paint consumption, reduces environmental impact, and effectively manages waste generated during painting operations. Through these efforts, Saelim GMT is providing sustainable painting solutions.

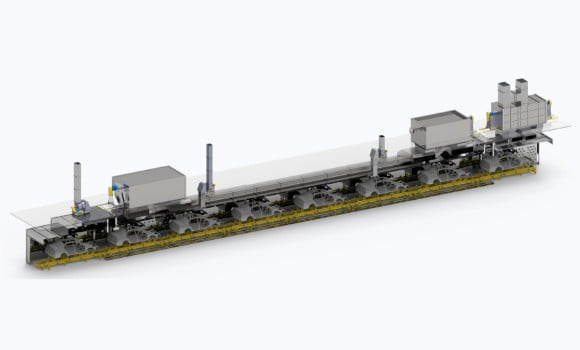

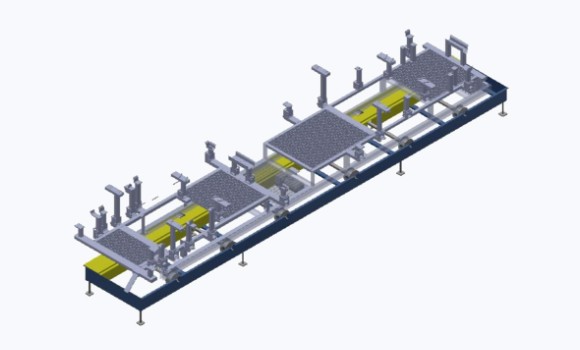

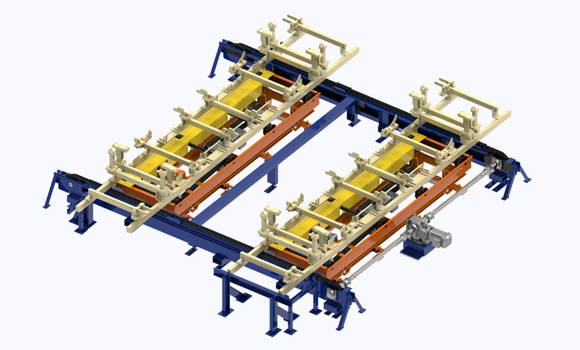

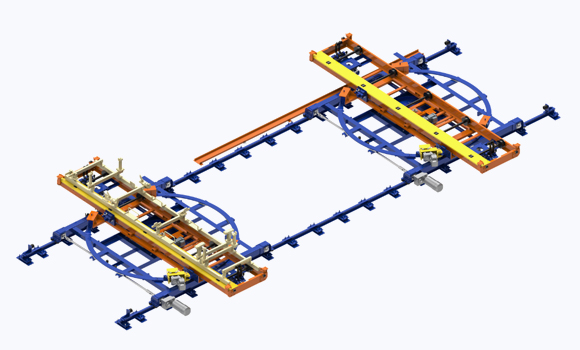

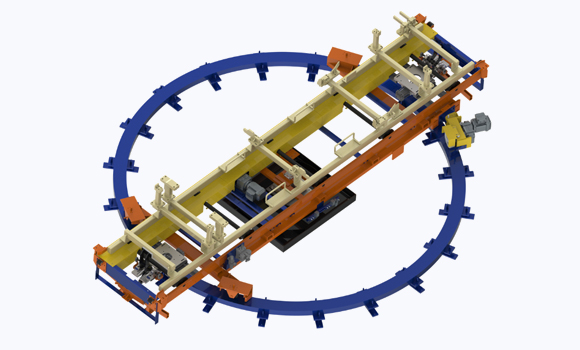

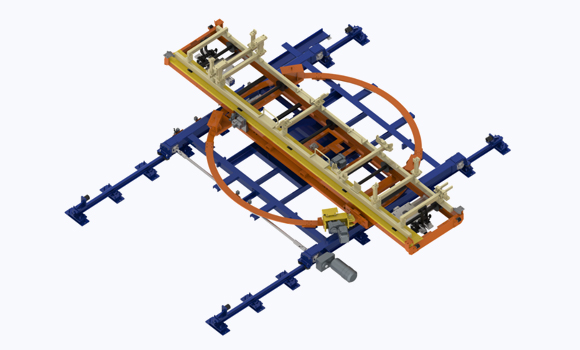

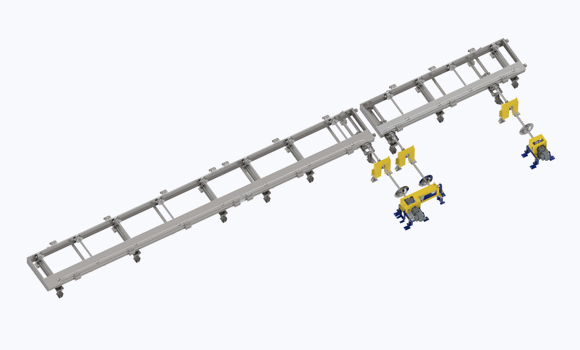

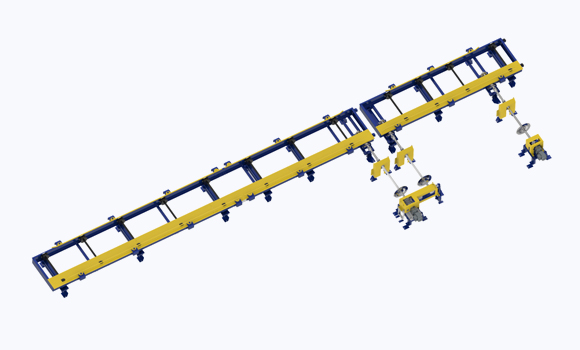

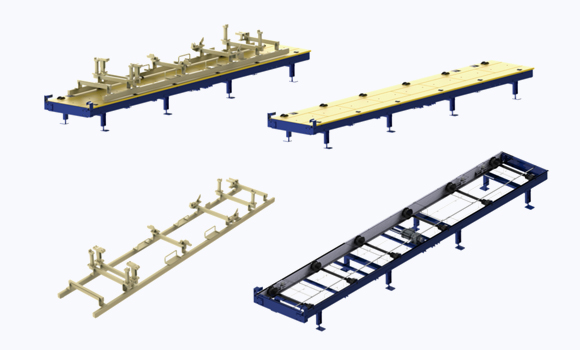

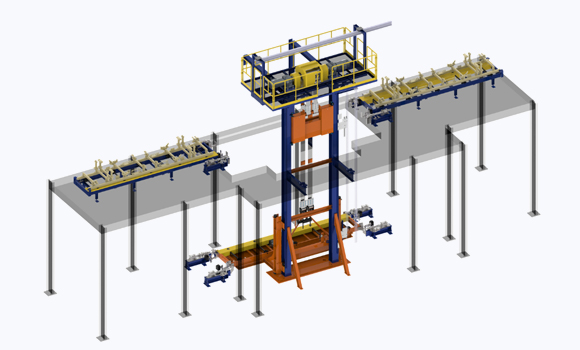

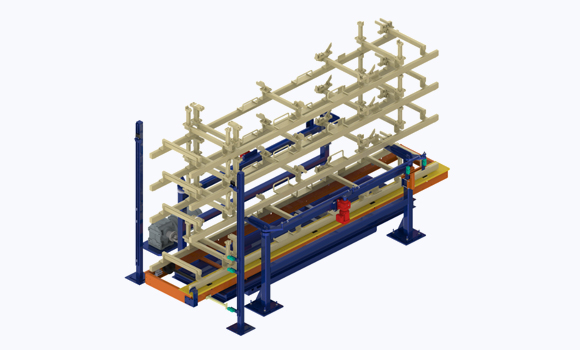

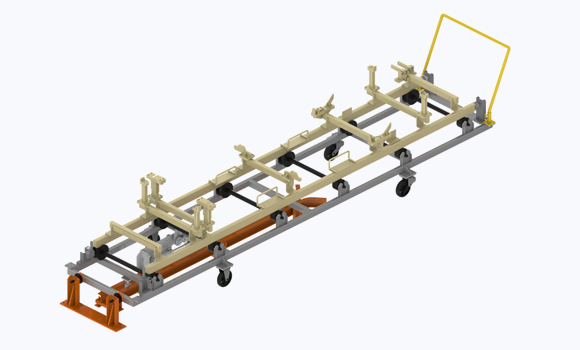

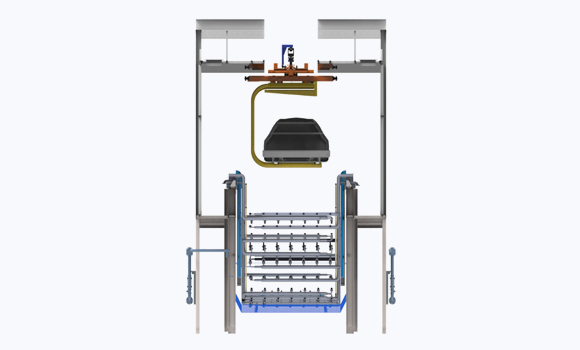

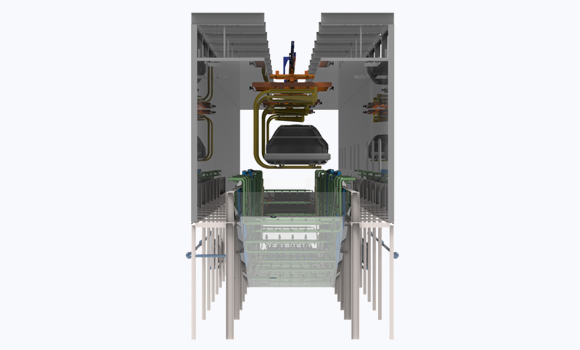

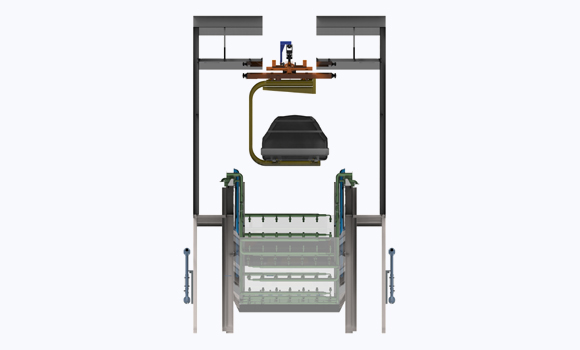

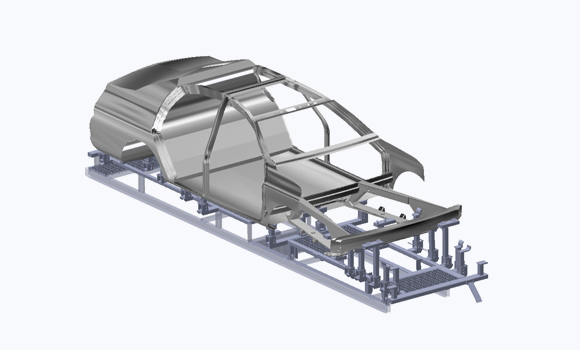

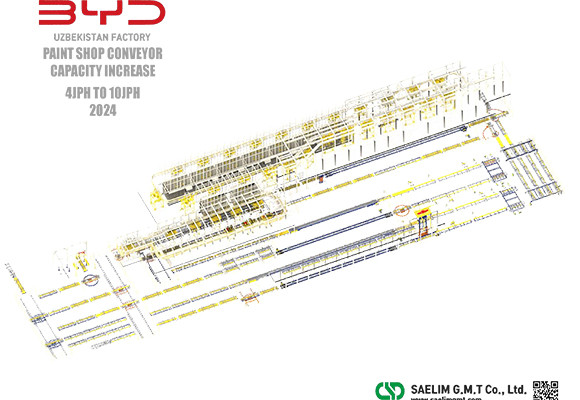

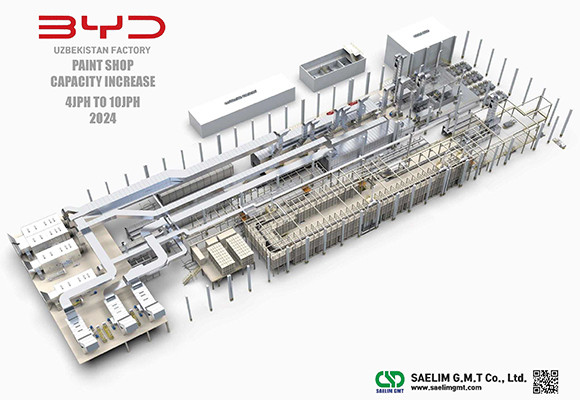

Conveyor Systems

Conveyor systems are an essential component of any paint plant and play a vital role in safely transporting products through the work area.

Saelim GMT provides the essential systems to achieve efficient and optimized quality in the painting process through conveyor systems. This allows you to automate the production process, improve throughput, and maintain consistent product quality. Saelim GMT's conveyor systems ensure efficient productivity while maintaining a safe working environment.

Other equipment

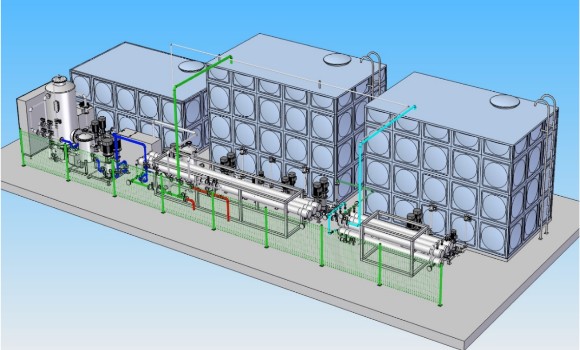

01DEIONIZER SYSTEM

This device plays an important role in various aspects of the automotive painting process, such as improving quality, increasing productivity, and protecting materials.

Deionizing water improves the quality of the water used in the paint, which improves the appearance of the paint. Using pure water also reduces water contamination that may occur during the paint process, protects the material, and extends the life of the paint material. This improves productivity and reduces work time.

02ULTRA FILTER (U.F) Filtration system

This plays an important role in maintaining overall process efficiency and minimizing material waste.

During the electrodeposition process, there are times when the unplated paint remaining on the surface of the coating material being withdrawn from the electrodeposition tank needs to be washed and recovered. At this time, an electrodeposition paint extraction device is used. This device washes and recovers the surface where the electrodeposition paint remains, making it recyclable.

03FILTER PRESS

This device continuously removes deposits as they form, playing an important role in ensuring efficient processing and maintaining equipment performance.

In the pretreatment film formation process, the precipitates that are formed due to oxidation during the process of precipitating the coating material must be continuously removed. A device that continuously removes them is used for this purpose.

04HYDRO CYCLONE

Hydro cyclones are used in automotive paint facilities to separate paint particles and water generated during the painting process.

During painting, overspray occurs, where excessive paint is sprayed into the air or washed off with water. During this process, the oversprayed paint particles and water mix together to create wastewater. HYDRO CYCLONE effectively removes paint particles from this wastewater, helping to recycle the water.

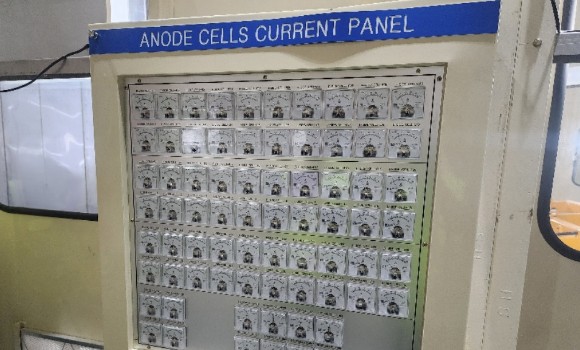

05RECTIFIER

Rectifiers are used to power electrically operated equipment in automotive paint shops.

They provide power to electrical spraying units, lighting and heating systems, control panels and control systems, and auxiliary equipment to support the painting process.